Efficient and transparent manufacturing processes and the traceability of materials and components are the aspects relevant to competition for medium-sized companies in the manufacturing industry today. These are made possible by a Manufacturing Execution System (MES), but the use of MES is still in its infancy in medium-sized companies. This can be remedied by a lean modular manufacturing solutions that offer a quick and easy entry into digital manufacturing processes and tracking and tracing "out of the box" within a few weeks.

With the help of modern IT systems, small and medium-sized manufacturing companies can benefit enormously from the potential that digital change and Industry 4.0 offer for optimizing manufacturing processes. Studies show that more than 80 percent of medium-sized industrial companies map their commercial processes in an ERP system. With regard to digitization, ERP makes "an elementary contribution to process management", as the industry association Bitkom states. The situation is completely different when manufacturing execution systems (MES) are used for the holistic consideration and control of production processes. This is still in its infancy in most SMEs' manufacturing, as a survey by Pierre Audoin Consultants (PAC) shows. Data on set-up and downtimes, on finished, good, and scrap quantities or on machine effectiveness (Overall Equipment Effectiveness, OEE), but also quality notifications are still recorded decentrally in many companies–in Excel files, self-developed databases and solutions, partly still on paper. The production and process data collected in this way must then be laboriously combined by hand to obtain Key Performance Indicators (KPI) that can be further evaluated. This is error-prone and has a negative impact on data quality. Above all, however, such an inhomogeneous database prevents a clear view of what is happening in production, with the result that the optimization potential in production-related processes is not sufficiently exploited. It also makes it virtually impossible to trace materials, components, and raw materials back to their source. Tracking and tracing in particular are an important prerequisite for complying with the guidelines of the Product Safety Act (ProdSG) or Good Manufacturing Practice (GMP) and thus preventing possible claims from product liability.

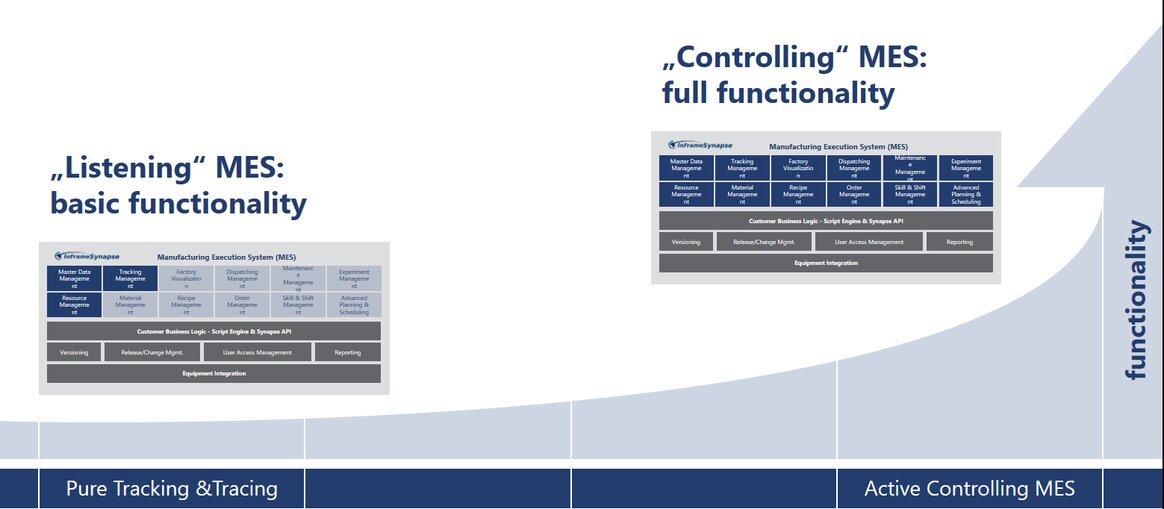

All this shows that small and medium-sized companies need a fast and cost-effective entry into the world of digital manufacturing processes and tracking and tracing. This is best done in the form of a slim and flexibly scalable application that can be implemented within a few weeks and allows the acquisition of production and process data without the need for complex system integration. This is especially true for companies that do not initially want to control their production with IT support and therefore do not require live data from their machines. If the solution also clearly visualizes Key Performance Indicators, such as throughput, scrap, product history, or OEE, this creates the necessary transparency to identify weaknesses in the production processes, determine their causes, and initiate optimization measures.

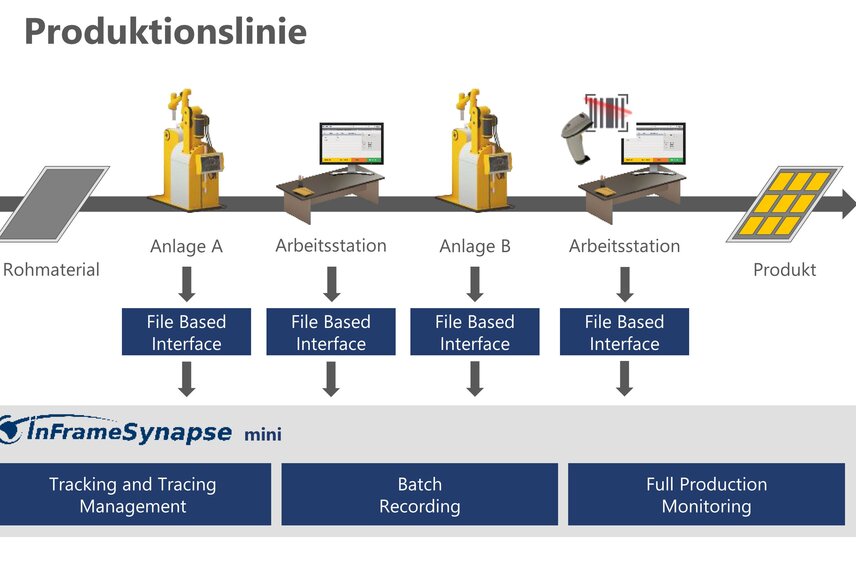

With InFrame Synapse MES mini from camLine, such a solution is already on the market. The web-based, modular application can be implemented and put into operation "out of the box" within four weeks. The acquisition of data and values from production-related systems is quite easy with this solution. A special function collects semi-automatically the production and process data provided by the machines or controllers in the form of text or Excel files: for example, process times and parameters, product IDs, time stamps, workloads, downtimes, operating times, and alarms, but also qualifying data such as order number, consumables, or measuring positions.

But the manufacturing solution offers a number of other advantages. It is scalable and can easily grow with the company. Firstly, its technical infrastructure can be flexibly adapted to the data volume, the number of individual servers, clusters, machines, or data sources. On the other hand, thanks to the modular structure of the application, the range of functions can be expanded relatively easily step by step up to a fully comprehensive MES.

InFrame Synapse MES mini is based on the free MySQL Community Server and therefore runs on all common operating system platforms (Windows/Linux) making the acquisition of additional third-party database servers unnecessary. Since the application can be linked to the other IT solutions used in the company, for example to an ERP system, the data collected from production-related systems can also be integrated into commercial processes. In this way, production can react more flexibly to market fluctuations and the quality of the products can also be continuously improved.

Read a more detailed German article on the subject in the magazine IT&Production www.it-production.com.

Contact: Frank Bölstler, camLine Dresden GmbH

frank.boelstler@camLine.com

As a leading conference for the microtechnology industry, the IVAM Hightech Summit offers a unique platform for experts and deciders …

Raith GmbH, internationally operating manufacturer of equipment and solutions for nanofabrication, has been certified in accordance with ISO 9001:2015 by …

The demand for electronics that operate at low temperatures is growing and becoming ever more important, especially for applications in …