On September 02–03, 2025, the 43rd Chemnitz Seminar will take place at Fraunhofer ENAS in Chemnitz. This year’s event focuses …

This week, IVAM member Laser Zentrum Hannover e.V. (LZH) will showcase cutting-edge photonic technologies at the LASER World of PHOTONICS …

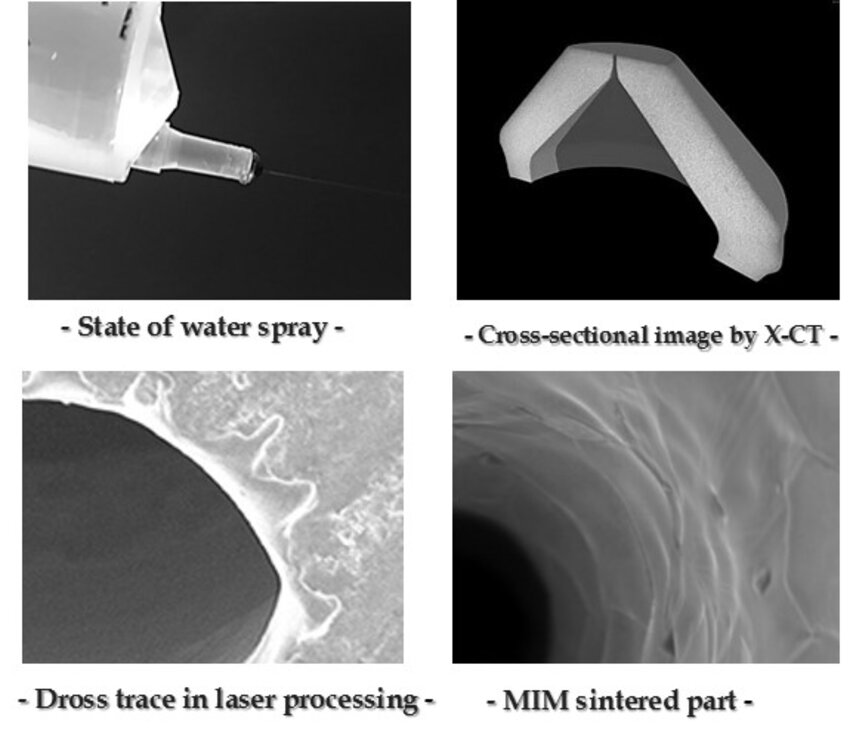

Fraunhofer ILT has developed a method that allows permeability to be created in metal components directly during 3D printing – …