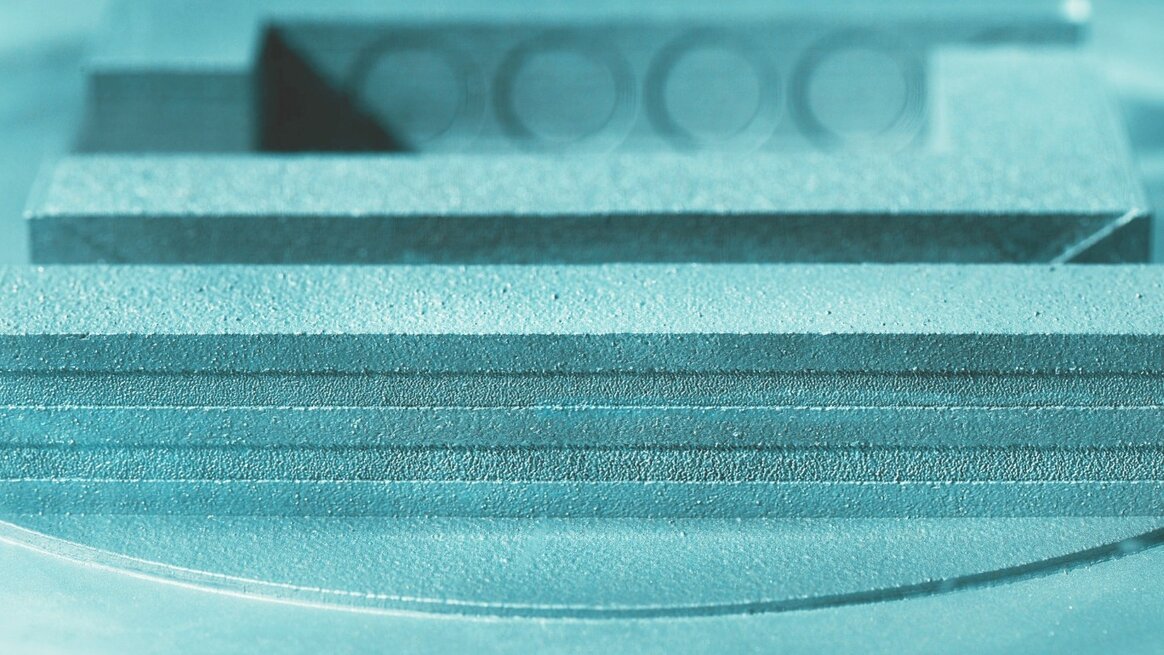

Fraunhofer ILT has developed a new process that enables the additive manufacturing of metal components with locally defined permeability or density—without any post-processing. This is made possible by precisely controlling porosity within the established Laser Powder Bed Fusion (LPBF) process. Transitions between dense and porous regions can be sharp or smoothly graded. The result: functionally integrated components with mechanical stability and tailored permeability.

Conventional metal foams or mesh structures typically need to be produced separately and then integrated into components. This is time-consuming, limits design flexibility, and often alters physical properties due to seams and joints—such as increased thermal or electrical resistance. The Fraunhofer approach integrates porous zones directly into the part. No additional processing is needed, and even complex internal geometries can be manufactured in one step.

The technology is especially promising for industries where gases or liquids must be precisely guided or filtered. A key area of application is hydrogen technology, specifically electrolyzers. These consist of complex cell stacks with multiple functional layers. Fraunhofer ILT is currently investigating whether these layers can be additively manufactured—including targeted permeable zones. The aim is to reduce the number of individual parts and improve efficiency, material use, and production costs.

Fraunhofer ILT is also in contact with end users in other fields such as turbomachinery, toolmaking, heat exchangers, filtration, and the chemical industry. The wide range of possible applications highlights the relevance of this innovation for high-tech industries.

Fraunhofer ILT will showcase this innovation live at Laser World of Photonics this week in Munich. A metallic logo with integrated porous zones demonstrates how air can be selectively channeled through the part—at the push of a button. Visitors are warmly invited to share their ideas at the Fraunhofer joint booth (Hall A3, Booth 431).

The rapid developments in energy and mobility sectors are driving the need for new solutions. The energy transition and the …

The Fraunhofer Institute for Laser Technology ILT has developed a laser deburring process that significantly improves the quality of metal …

The optical industry almost completely relies on mechanical processes in its process chains. This, however, could soon change. The Fraunhofer …