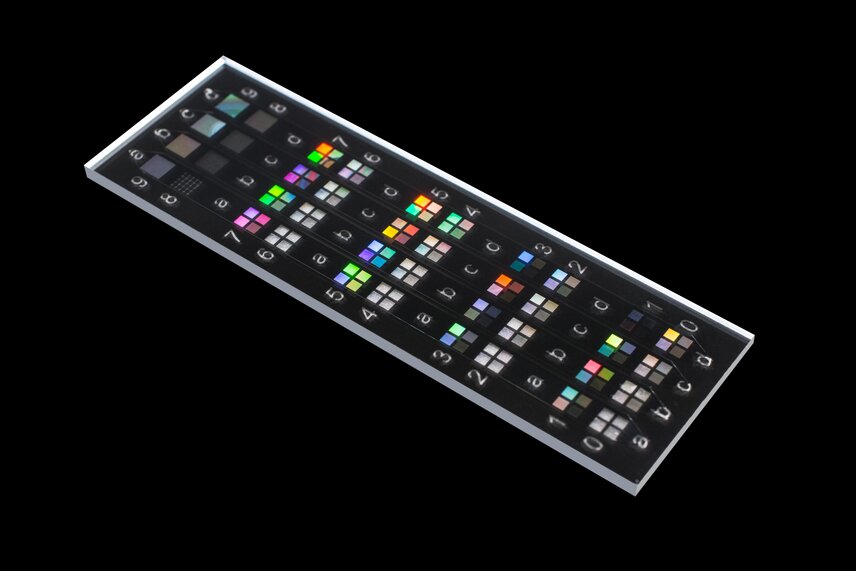

IMT AG is the provider of leading-edge BioMEMS technology transferring the microfabrication expertise originally developed for microelectronics (MEMS) into flexible and scalable solutions for the manufacturing of micro- and nanostructures in glass for consumables in life science applications and components in medical instruments and equipment. With more than 50 years of experience in the fields of optics and metrology, IMT AG is well-positioned in the intersection of microfluidic and photonics to act as a development partner, as well as a large-scale manufacturer of glass consumables for microfluidic and biophotonic applications. At the point where microfluidics, biotechnology and optics overlap and require a multidisciplinary approach and a wide range of processes conducted by employees with a well-founded understanding of the process and application, IMT offers partnership. A flexible processes that enable customized microfluidic solutions in glass: design consultancy, prototyping and scalable manufacturing for application such as NGS, organ-on-a-chip, lab-on-a-chip, single-cell analysis, cell enrichment, sample preparation and many more.

Applications such as next-generation sequencing (NGS), cell selection and organ-on-a-chip technologies all benefit from the ability to pattern nanofeatures in glass microchannels. NGS transduction approaches may have challenging detection requirements such as measuring single oligonucleotide fluorescence with SBS. Additionally, cell encapsulation, droplet digital PCR, sample-to-answer qPCR and digital PCR microfluidic cartridges, encompassing cell enrichment, isolation, lysis, biomolecular sample prep, and PCR amplification/quantitation require partial functionalization and integration of electronic read-out concepts. By employing thermally and UV-A-cured adhesives, it is possible to perform room-temperature bonding processes on glass, allowing for bio-molecule encapsulation prior to bonding. The automation of UV-adhesive bond equipment simplifies and reduces costs for manufacture.

Contact: IMT Masken und Teilungen AG,

info@imtag.ch

As of August 1, 2025, Bartels Mikrotechnik proudly welcomes Florian Siemenroth as Co-Managing Director. Together with Monika Kremer, he will …

Dr. Matthias Jahncke is the new Managing Director of HNP Mikrosysteme GmbH. He takes over from Dr. Thomas Weisener, who …

On September 02–03, 2025, the 43rd Chemnitz Seminar will take place at Fraunhofer ENAS in Chemnitz. This year’s event focuses …